Fiber optic cables are a revolutionary technology that has transformed the way we communicate and transmit data. But have you ever wondered where the hardware in a fiber optic cable is located? In this article, we will explore the hidden hardware components in fiber optic cables and how they work together to provide us with fast and reliable connectivity. From the physical structure of the cable to the various components that make up the system, we will delve into the fascinating world of fiber optics and discover the technology that powers our digital age. So, let’s get started and uncover the secrets behind this amazing technology!

What are Fiber Optic Cables?

History of Fiber Optic Cables

The development of fiber optic cables can be traced back to the late 19th century when researchers first discovered the concept of total internal reflection. In 1880, a German physicist named Heinrich Hertz discovered that light could be transmitted through a transparent medium, such as glass or water, by means of vibrations of the medium. However, it was not until the early 20th century that researchers began to explore the potential of using light to transmit information over long distances.

One of the first major breakthroughs in fiber optic technology came in 1925, when a physicist named Arthur Schawlow proposed the idea of using a glass fiber to transmit light. Schawlow’s idea was to use a thin glass rod with a high refractive index, which would allow light to be transmitted through the rod with minimal loss of energy. This concept was further developed by a team of researchers at Bell Labs in the 1950s, who experimented with using thin threads of glass to transmit light over long distances.

The first practical fiber optic cable was developed in the 1960s by a team of researchers at the Corning Glass Works laboratory. This cable, known as the “Corning Cable,” was made from a thin strand of glass that was coated with a reflective material to prevent light from leaking out. The Corning Cable was the first fiber optic cable to be commercially available, and it was used in a variety of applications, including telecommunications and medical equipment.

In the following decades, fiber optic technology continued to evolve and improve. Today, fiber optic cables are widely used in a variety of industries, including telecommunications, healthcare, and transportation. The development of fiber optic technology has had a profound impact on modern society, enabling faster and more efficient communication, improved medical care, and new forms of entertainment and media.

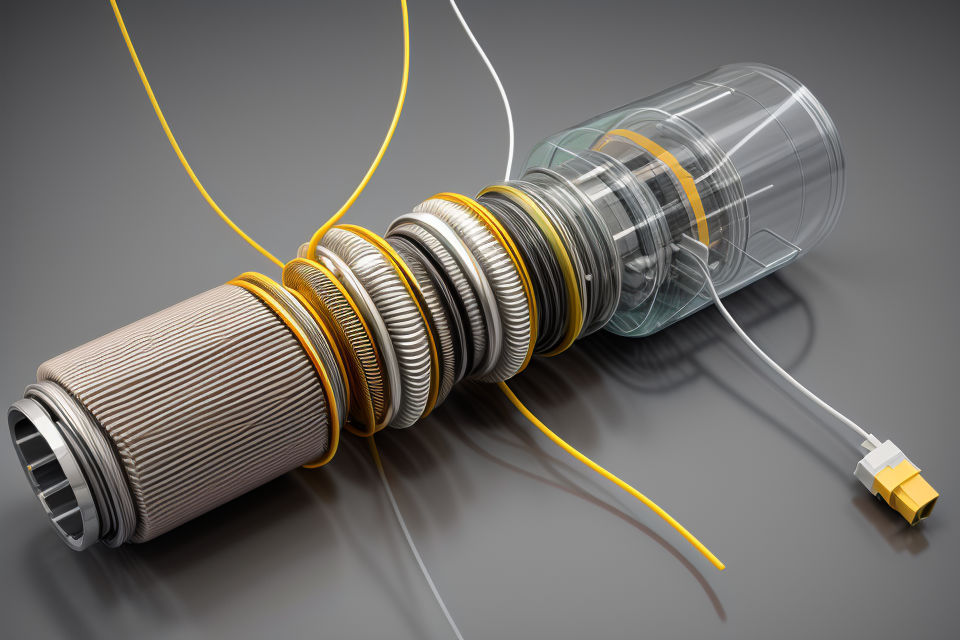

Composition of Fiber Optic Cables

Fiber optic cables are made up of a core, cladding, and a protective coating. The core is the central part of the cable that carries the light signal, while the cladding surrounds the core and reflects the light back into the core. The protective coating is used to shield the cable from damage.

The core of the fiber optic cable is typically made of high-purity glass or plastic, and it is extremely thin, with a diameter of only a few microns. The cladding is made of a different material than the core, and it is also thin, with a diameter of about 100 microns. The protective coating is thicker than the cladding, and it can be made of materials such as polyethylene or Kevlar.

The core and cladding are designed to work together to allow the light signal to travel through the cable with minimal loss. The core is typically made of a material that is highly transparent to light, while the cladding is made of a material that is less transparent. This allows the light signal to be reflected back into the core, rather than being absorbed by the cladding.

The composition of fiber optic cables is carefully designed to ensure that the light signal can travel through the cable with minimal loss and interference. By understanding the components of fiber optic cables, it is possible to better understand how they work and how to optimize their performance.

Fiber Optic Cable Hardware Components

Connector Hardware

SC, LC, and FC Connectors

SC, LC, and FC connectors are three common types of connector hardware used in fiber optic cables. These connectors are designed to secure and join the ends of fiber optic cables together, ensuring that the signal can be transmitted effectively.

- SC (Subscriber Connector) connectors have a push-pull mechanism and are commonly used in telecommunications applications. They have a high durability and are resistant to damage from pulling and twisting.

- LC (Lucent Connector) connectors are smaller and lighter than SC connectors, making them popular for use in data centers and other high-density applications. They have a latch mechanism that provides a secure connection.

- FC (Ferrule Connector) connectors have a spring-loaded ferrule that grips the fiber optic cable and provides a precise connection. They are commonly used in high-end applications such as scientific research and telecommunications.

Other Types of Connectors

In addition to SC, LC, and FC connectors, there are other types of connector hardware used in fiber optic cables. Some examples include:

- ST (Straight Tip) connectors: These connectors have a bayonet-style locking mechanism and are commonly used in multi-mode fiber optic cables.

- BIC (Bayonet Interface Connector) connectors: These connectors have a push-pull mechanism and are commonly used in single-mode fiber optic cables.

- MPO (Multi-Fiber Optic) connectors: These connectors are used for high-density applications and can accommodate up to 72 fibers in a single connector.

Connector hardware plays a critical role in the performance and reliability of fiber optic cables. Choosing the right connector for a specific application is essential to ensure optimal signal transmission and long-term durability.

Optical Hardware

Optical hardware is a crucial component of fiber optic cables. It is responsible for transmitting data signals over long distances through light waves. In this section, we will delve into the details of two types of optical hardware: Optical Fiber Concentrators and Optical Amplifiers.

Optical Fiber Concentrators

Optical fiber concentrators are devices that increase the optical signal strength and allow for more efficient transmission of data. They work by combining multiple optical fibers into a single fiber, which increases the overall bandwidth and signal strength. There are two types of optical fiber concentrators: passive and active.

Passive optical fiber concentrators use mirrors to combine the signals from multiple fibers into a single fiber. This type of concentrator is relatively simple and inexpensive, but it suffers from high signal loss and limited bandwidth.

Active optical fiber concentrators, on the other hand, use active components such as semiconductor amplifiers to amplify the signals before combining them. This type of concentrator has a lower signal loss and higher bandwidth compared to passive concentrators.

Optical Amplifiers

Optical amplifiers are devices that amplify the optical signal in fiber optic cables. They work by using a gain medium, such as a doped fiber or a rare earth material, to amplify the signal. There are two types of optical amplifiers: erbium-doped fiber amplifiers (EDFAs) and rare earth doped fiber amplifiers (REDFAs).

EDFAs are the most commonly used type of optical amplifier. They work by using a doped fiber to amplify the signal, and they have a gain bandwidth of around 1.5 nm. EDFAs are used in long-haul fiber optic networks to amplify signals over long distances.

REDFAs, on the other hand, use rare earth materials such as erbium, holmium, or thulium to amplify the signal. They have a wider gain bandwidth compared to EDFAs, and they are used in applications that require high power and broadband amplification, such as laser radiation, medical imaging, and telecommunications.

In conclusion, optical hardware is a critical component of fiber optic cables. Optical fiber concentrators and optical amplifiers play a vital role in transmitting data signals over long distances. Understanding the intricacies of these components is essential for designing and optimizing fiber optic networks.

Hardware Accessories

Fiber optic patch cables are a type of hardware accessory that are used to connect two fiber optic devices, such as a switch or a router, together. These cables are made up of a thin strand of glass or plastic, known as the core, which is surrounded by a layer of cladding material. The cladding material helps to keep the light signal within the core of the cable, allowing it to travel further and with less loss of signal.

Fiber optic patch cables come in a variety of different types, including single-mode and multimode cables. Single-mode cables have a smaller core diameter, which allows them to transmit data over longer distances with less signal loss. Multimode cables, on the other hand, have a larger core diameter, which makes them better suited for shorter distance connections.

Fiber optic splice closures are another type of hardware accessory that are used in fiber optic networks. These closures are designed to provide a secure and reliable connection between two fiber optic cables. They work by physically splicing the two cables together, creating a single, unbroken connection. This helps to reduce the risk of signal loss or interference, and ensures that the network can operate at maximum capacity.

In addition to providing a secure connection between cables, fiber optic splice closures also help to protect the cables themselves from damage. They are typically made from a durable material, such as metal or plastic, which helps to shield the cables from physical stress and environmental factors, such as moisture and temperature changes. This helps to ensure that the network remains reliable and operates at maximum capacity over time.

Understanding the Importance of Fiber Optic Hardware

Durability and Reliability

When it comes to the components of fiber optic cables, durability and reliability are key factors that cannot be overlooked. These hardware components are responsible for ensuring that the fiber optic cable can withstand the test of time and provide a consistent, high-quality signal.

One of the main reasons why fiber optic cables are considered to be more durable than traditional copper cables is due to their construction. Unlike copper cables, which are prone to breaking and wearing down over time, fiber optic cables are made from a flexible, yet sturdy material that is resistant to damage. This means that they can be bent and twisted without suffering any harm, making them ideal for use in environments where they may be subjected to rough handling.

Another factor that contributes to the durability of fiber optic cables is their resistance to interference. Unlike copper cables, which can be affected by electromagnetic interference, fiber optic cables are immune to this type of interference. This means that they can be used in environments where there is a lot of electrical activity, such as near power lines or radio transmitters, without experiencing any degradation in signal quality.

In addition to their durability, fiber optic cables are also known for their reliability. Because they use light to transmit data, rather than electricity, they are less prone to signal degradation over long distances. This means that they can be used to transmit data over longer distances without experiencing any loss of quality.

Overall, the durability and reliability of fiber optic cables make them an ideal choice for a wide range of applications, from telecommunications to medical imaging. By investing in high-quality fiber optic hardware, businesses and organizations can ensure that they are able to transmit data with ease and confidence, knowing that their signal will remain strong and consistent over time.

Ease of Installation and Maintenance

One of the primary advantages of fiber optic hardware is the ease of installation and maintenance. This is due to the lightweight and compact nature of the components used in fiber optic cables. Here are some key points to consider:

- Simplified Installation Process: Fiber optic cables are much lighter and more flexible than traditional copper cables, making them easier to handle and install. This means that installation can be done more quickly and with less physical effort, which can reduce labor costs and improve productivity.

- Reducing Installation Complexity: The small size and weight of fiber optic hardware make it easier to maneuver in tight spaces, such as in building interiors or in underground installations. This reduces the complexity of the installation process and makes it more feasible to install in challenging environments.

- Lower Maintenance Requirements: The components used in fiber optic cables are less prone to damage than copper cables, which reduces the need for maintenance. Fiber optic cables are less susceptible to physical damage, such as being crushed or bent, which can cause problems in copper cables. Additionally, fiber optic cables are less affected by electromagnetic interference, which can also reduce maintenance requirements.

- Easier Troubleshooting: The use of fiber optic hardware simplifies troubleshooting and diagnostics. Since the components are lightweight and compact, they are easier to access and inspect, which makes it easier to identify and fix problems. Additionally, fiber optic cables have built-in diagnostic capabilities, which can provide valuable information about the health of the cable and help identify potential issues.

Overall, the ease of installation and maintenance of fiber optic hardware is a significant advantage that makes it an attractive option for many applications. By reducing the complexity and cost of installation and maintenance, fiber optic cables can help businesses and organizations save time and money while improving the quality of their communications infrastructure.

Scalability and Future-Proofing

Scalability and future-proofing are two essential factors to consider when discussing the importance of fiber optic hardware.

Scalability

Scalability refers to the ability of a system to grow and adapt to changing demands. In the context of fiber optic cables, scalability is crucial because it allows the network to accommodate an increasing number of users and devices without compromising performance. Fiber optic hardware plays a significant role in ensuring that the network can be easily scaled up as needed.

One way that fiber optic hardware enables scalability is through the use of high-density connectors. These connectors allow for more fibers to be packed into a smaller space, making it possible to increase the capacity of the network without having to replace the entire cable infrastructure. Additionally, some fiber optic hardware components, such as optical line terminals (OLTs), are designed to be modular, which means that they can be easily upgraded or replaced as new technologies are developed.

Future-Proofing

Future-proofing refers to the ability of a system to withstand changes and advancements in technology without becoming obsolete. Fiber optic hardware is essential for future-proofing because it allows the network to keep up with the latest technological advancements.

One way that fiber optic hardware enables future-proofing is through its ability to support higher bandwidths. As new applications and services are developed that require more bandwidth, fiber optic hardware can be upgraded to support these demands. For example, many fiber optic cables are now being installed with a higher fiber count, which allows for greater bandwidth capacity.

Another way that fiber optic hardware enables future-proofing is through its ability to support new transmission technologies. For example, some fiber optic hardware components, such as reconfigurable optical add-drop multiplexers (ROADMs), are designed to be compatible with different wavelength division multiplexing (WDM) technologies, which allow for the transmission of multiple signals over a single fiber optic cable. This means that as new transmission technologies are developed, the network can be easily upgraded to support them without having to replace the entire cable infrastructure.

In conclusion, scalability and future-proofing are two critical factors to consider when discussing the importance of fiber optic hardware. The ability to easily scale the network and keep up with changing technological demands is essential for ensuring that the network can meet the needs of its users and continue to evolve over time.

Fiber Optic Hardware Challenges and Innovations

Fiber Optic Hardware Compatibility Issues

In the rapidly evolving world of fiber optic technology, hardware compatibility issues have emerged as a significant challenge. As manufacturers introduce new devices and components to the market, ensuring that these components are compatible with existing systems can be a daunting task.

One of the primary reasons for hardware compatibility issues is the sheer diversity of available components. With countless manufacturers offering a vast array of products, it can be difficult to ensure that each component will work seamlessly with the others. Moreover, as the industry continues to evolve, it becomes increasingly challenging to maintain compatibility across various generations of hardware.

Another factor contributing to compatibility issues is the rapid pace of technological advancement. As new technologies are developed, existing hardware may become obsolete, necessitating the purchase of new components that may not be compatible with the existing system. This can lead to costly upgrades and disruptions in service.

Furthermore, fiber optic hardware compatibility issues can also arise due to differences in manufacturing standards. As different manufacturers adhere to various standards, ensuring that components from different manufacturers will work together can be a complex process. This can result in costly and time-consuming compatibility testing, which can delay the deployment of new systems.

To address these challenges, manufacturers and industry experts are working together to establish standardized specifications for fiber optic hardware. These specifications aim to ensure that components from different manufacturers will work together seamlessly, reducing the need for costly and time-consuming compatibility testing.

Additionally, the development of modular hardware systems has enabled greater flexibility in hardware configuration. These systems allow for the integration of various components, making it easier to upgrade and maintain existing systems without sacrificing compatibility.

Overall, fiber optic hardware compatibility issues represent a significant challenge in the industry. However, through the establishment of standardized specifications and the development of modular hardware systems, manufacturers and industry experts are working to overcome these challenges and ensure seamless compatibility across a wide range of hardware components.

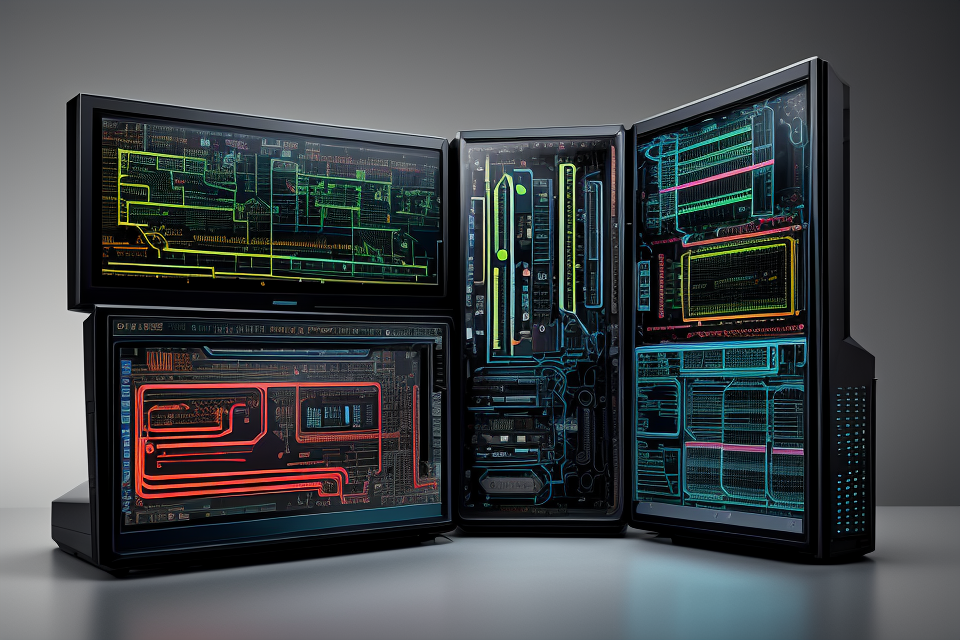

Fiber Optic Hardware Innovations

Fiber optic technology has undergone significant innovations in recent years, resulting in improved performance, reliability, and cost-effectiveness. Some of the key hardware innovations in fiber optic technology include:

- Development of high-speed transceivers: Transceivers are devices that convert electrical signals to optical signals and vice versa. The development of high-speed transceivers has enabled the transmission of data at faster speeds and over longer distances. These transceivers are also designed to be more energy-efficient, which helps reduce the overall cost of fiber optic networks.

- Improved cable design: The design of fiber optic cables has also undergone significant improvements. For example, the use of tight buffered fibers has reduced the need for additional protective jackets, making the cables lighter and more flexible. Additionally, the use of more advanced materials has increased the durability and longevity of the cables.

- Enhanced network management tools: Fiber optic networks require sophisticated management tools to ensure optimal performance and reliability. New software tools have been developed that can monitor network performance in real-time, detect and diagnose problems, and provide detailed analytics on network traffic. These tools have greatly improved the management and maintenance of fiber optic networks.

- Advancements in optical amplifiers: Optical amplifiers are used to boost the signal strength of optical signals as they travel through the network. Recent innovations in optical amplifier technology have led to more efficient and reliable amplifiers, which can improve the overall performance of the network.

- Integration of artificial intelligence: Artificial intelligence (AI) is being integrated into fiber optic networks to automate many tasks and improve network performance. For example, AI algorithms can be used to predict network congestion and optimize traffic flow, reducing latency and improving overall network performance.

Overall, these hardware innovations have greatly improved the performance and reliability of fiber optic networks, making them an increasingly popular choice for businesses and consumers alike.

Fiber Optic Hardware and Environmental Impact

As fiber optic technology continues to advance, it is crucial to consider the environmental impact of the hardware components used in these systems. Fiber optic hardware, like other electronic devices, can contribute to electronic waste and pollution if not designed and disposed of properly.

- E-waste: Electronic waste, or e-waste, is a growing problem worldwide. As more fiber optic cables and components are produced and discarded, the amount of e-waste increases. This waste can contain hazardous materials such as lead, mercury, and cadmium, which can contaminate soil and water sources if not disposed of properly.

- Environmentally friendly design: To mitigate the environmental impact of fiber optic hardware, manufacturers are designing products with sustainability in mind. This includes using recyclable materials, reducing the use of hazardous substances, and designing products that can be easily disassembled and recycled.

- End-of-life management: Proper end-of-life management is essential to minimize the environmental impact of fiber optic hardware. This includes responsible disposal methods, such as recycling and safe disposal, as well as promoting the reuse of hardware components.

- Consumer responsibility: Consumers also play a role in reducing the environmental impact of fiber optic hardware. By choosing products from manufacturers who prioritize sustainability and responsible end-of-life management, consumers can make a difference in reducing e-waste and pollution.

In conclusion, the environmental impact of fiber optic hardware cannot be ignored. By considering the environmental challenges associated with these components, manufacturers and consumers can work together to reduce e-waste and promote sustainability in the fiber optic industry.

The Future of Fiber Optic Hardware

Advancements in Material Science

One of the most promising areas of research for the future of fiber optic hardware is the development of new materials that can improve the performance of fiber optic cables. This includes the use of novel materials like photonic crystal fibers, which have the potential to significantly increase the bandwidth of fiber optic cables.

Integration with Other Technologies

Another area of focus for the future of fiber optic hardware is the integration of fiber optic technology with other communication technologies. This includes the development of hybrid fiber-coaxial cables, which can provide both high-speed data transmission and cable television services.

Improved Manufacturing Processes

Improved manufacturing processes are also a key area of focus for the future of fiber optic hardware. This includes the development of new techniques for drawing and processing fiber optic cable, as well as the use of automation and robotics to improve the efficiency and accuracy of the manufacturing process.

Environmental Sustainability

Environmental sustainability is also an important consideration for the future of fiber optic hardware. This includes the development of more environmentally friendly manufacturing processes, as well as the use of recyclable materials in the production of fiber optic cables.

Cost Reduction

Finally, cost reduction is a critical area of focus for the future of fiber optic hardware. This includes the development of new manufacturing processes that can reduce the cost of producing fiber optic cables, as well as the use of new materials that can reduce the overall cost of fiber optic hardware.

Recommended Resources for Further Reading

For those interested in delving deeper into the challenges and innovations surrounding fiber optic hardware, there are several recommended resources available. These resources offer a wealth of information on the latest developments, advancements, and trends in the field of fiber optic hardware.

- Books:

- “Fiber Optic Communications: A Signal Processing Approach” by Govind P. Agrawal

- “Fiber Optic Technologies: An Introduction” by David A. Hagan

- “Fiber Optic Networks: An Introduction” by P. Kumar

- Journals and Magazines:

- Optics Express

- Journal of Lightwave Technology

- Optics and Photonics News

- Online Resources:

- Fiber Optic Association: Provides comprehensive information on fiber optic technology, applications, and industry news.

- The Optical Society (OSA): A leading organization for scientists, engineers, and business professionals in the field of optics and photonics.

- Fiber Optic Center: Offers a range of resources on fiber optic technology, including articles, tutorials, and videos.

These resources provide valuable insights into the world of fiber optic hardware, including cutting-edge research, real-world applications, and the latest advancements in the field.

FAQs

1. What is the purpose of hardware in fiber optic cables?

The hardware in fiber optic cables is used to transmit data signals over long distances with minimal signal loss. It consists of various components such as connectors, cable markers, and cable management systems that help to ensure the integrity of the signal and prevent damage to the cable.

2. What are the main hardware components in fiber optic cables?

The main hardware components in fiber optic cables include connectors, cable markers, cable management systems, and splicing equipment. Connectors are used to join two or more fibers together, while cable markers are used to identify the fibers and their corresponding connections. Cable management systems are used to organize and protect the cables, while splicing equipment is used to join two or more fibers together.

3. What are the benefits of using hardware in fiber optic cables?

The benefits of using hardware in fiber optic cables include improved signal quality, increased reliability, and reduced signal loss. By using high-quality hardware components, such as connectors and cable management systems, fiber optic cables can be better protected from damage and signal loss, resulting in improved signal quality and increased reliability.

4. How is hardware installed in fiber optic cables?

Hardware is installed in fiber optic cables by trained professionals who use specialized tools and equipment. The process typically involves preparing the fibers and connectors, inserting the connectors into the fibers, and securing the connections using cable management systems. Splicing equipment may also be used to join two or more fibers together.

5. What are some common issues with hardware in fiber optic cables?

Some common issues with hardware in fiber optic cables include poor connector quality, incorrect cable management, and improper splicing. These issues can result in signal loss, increased attenuation, and decreased reliability. It is important to ensure that hardware components are of high quality and installed correctly to prevent these issues.